Roll forming to tight tolerances is our specialty

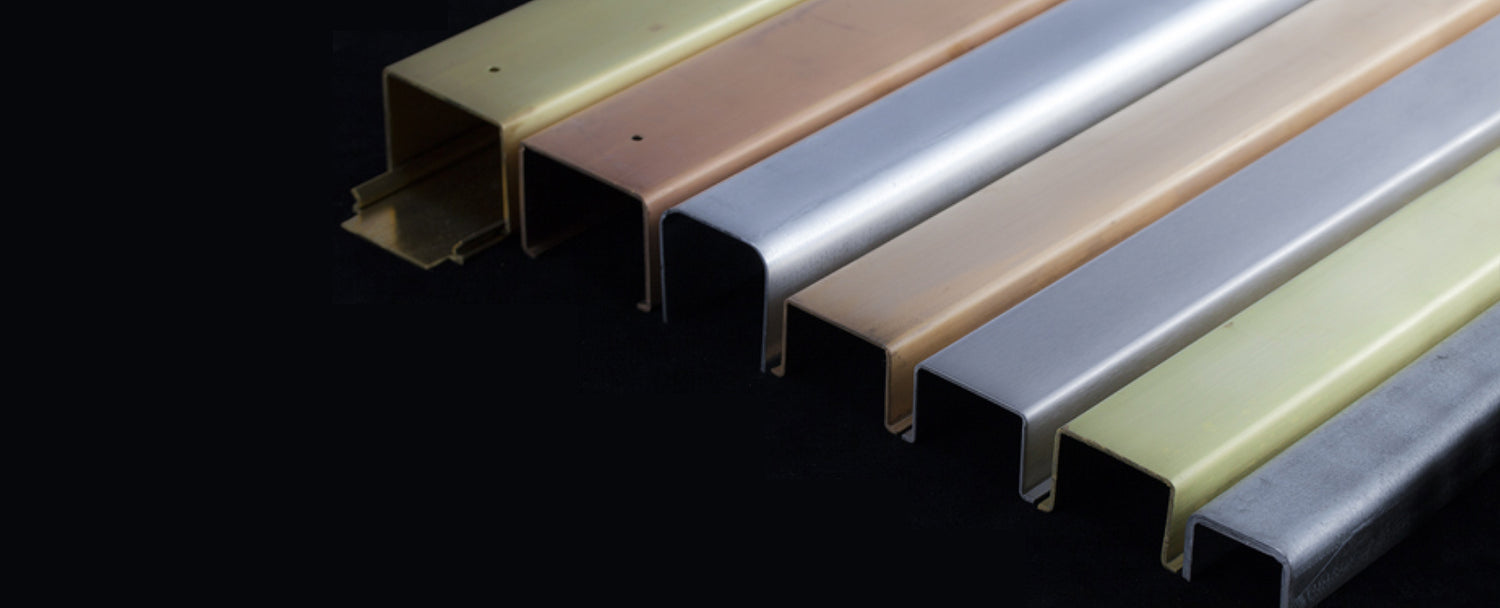

We produce both standard roll formed sections and custom roll formed profiles utilizing the most advanced metal fabricating technology available today. Precision Rollform Technologies has been producing roll formed parts for over sixty years. Our experience includes the roll forming of just about any metal that is available in coil form such as cold rolled steel, stainless steel, hot rolled steel, galvanized steel, brass, bronze and aluminum. Over the years we have developed a large archive of roll form tooling for standard shapes such as "U" channels, angles and "hat" sections. We can pull these dies off the shelf and begin your roll forming production right away, or if necessary, make slight adjustments to fit your special requirements.

-

Standard Shapes

-

Custom Shapes

-

Precision Lockers